Industrial Coffee Grinder Selection Guide for Expert Coffee Makers

Industrial Coffee Grinder Selection Guide for Expert Coffee Makers

Blog Article

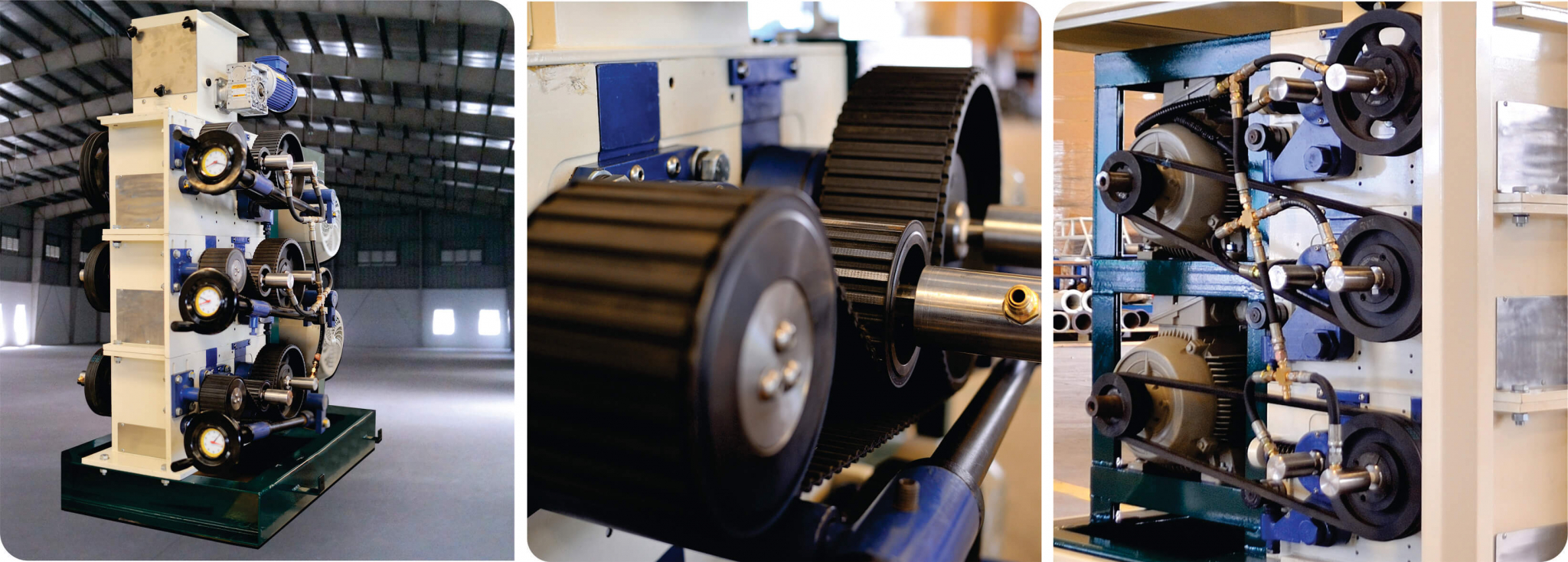

Industrial Coffee Mill Overview: Boost Efficiency and Top Quality

In the affordable landscape of coffee production, selecting the best commercial coffee grinder plays a crucial role in enhancing both performance and product quality. Comprehending the nuances of numerous mill kinds and crucial functions-- such as adjustable work settings and durable building-- can dramatically affect the final flavor profile of the coffee.

Comprehending Grinder Types

When picking a commercial coffee grinder, understanding the different types offered is crucial for optimizing both flavor extraction and operational effectiveness. The 2 primary types of mills are blade mills and burr grinders.

Eventually, choosing the right sort of grinder is indispensable to preserving high quality and efficiency in coffee production, making it vital for companies to spend in top notch burr mills for optimum results.

Secret Attributes to Think About

Picking an industrial coffee grinder requires cautious factor to consider of several essential functions that can considerably affect both efficiency and the general coffee experience. Among the key facets to review is the grinding mechanism. Burr grinders are normally favored over blade mills, as they offer a regular grind size, which is vital for optimal removal and flavor.

An additional essential function is the mill's ability. A functional mill with multiple settings permits you to tailor the grind dimension to different brewing approaches, enhancing the coffee's flavor account.

The building and construction material additionally contributes in toughness and upkeep. Stainless-steel components typically provide longevity and are less complicated to cleanse, which is necessary for maintaining hygiene criteria. Lastly, evaluate the mill's noise degree, especially in an active café or manufacturing environment, where excessive sound can be turbulent. Buying a grinder that balances these attributes can considerably enhance both operational performance and the top quality of the coffee offered.

Optimizing Grinding Process

To achieve the very best results in coffee preparation, optimizing the grinding procedure is necessary. The work size substantially affects removal, taste, and total high quality of the brewed coffee. Various developing approaches need certain work dimensions; as an example, coffee requires a great grind, while French press necessitates a rugged structure. Recognizing the connection in between grind size and brewing technique is the primary step in optimization.

Additionally, checking the grinding rate can maximize the process. Slower grinding often creates much less warmth, protecting fragile tastes and scents. Alternatively, faster grinding might produce extreme warm, negatively affecting the coffee's quality.

Maintenance and Care Tips

Appropriate maintenance and care of industrial coffee grinders are essential for making certain ideal efficiency and long life. Normal cleaning is the structure of maintenance; deposit buildup can influence taste and grinding efficiency. It is Homepage suggested to clean the mill after each use, wiping down the outside and getting rid of any kind of coffee grounds from the burrs.

Additionally, inspect the grinding burrs for deterioration. Plain burrs can compromise work consistency, so they ought to be replaced as necessary. Industrial Coffee Grinder. Periodically calibrating the mill is likewise crucial, as this maintains the wanted grind size for different developing techniques

Lubrication of moving parts ought to be carried out according to the producer's requirements, as this lowers rubbing and prolongs the life of the equipment. It is vital to make use of food-grade lubricating substances to make have a peek at these guys sure safety and security and compliance with wellness guidelines.

Last but not least, keep the grinder in a steady and dry atmosphere to stop rust and deterioration. By adhering to these maintenance and treatment pointers, operators can enhance the effectiveness of their industrial coffee mills while guaranteeing high-grade output and expanded operational life.

Roi Analysis

Assessing the return on investment (ROI) for industrial coffee grinders is crucial for services seeking to optimize their coffee manufacturing capabilities. A complete ROI evaluation assists determine the financial feasibility of buying premium grinders, permitting businesses to weigh why not try here the first costs versus potential gains.

Evaluate the acquisition price of the grinder, including setup and any necessary alterations to existing framework. High-performance grinders commonly lead to lowered grinding time and boosted throughput, which can substantially boost productivity.

In addition, consider the impact on item quality. Industrial Coffee Grinder. Superior grinders produce a more regular work size, which can improve taste profiles and consumer complete satisfaction, ultimately driving sales. By raising the quality of the end product, companies can warrant greater rates, leading to boosted income

Final Thought

In recap, an industrial coffee mill plays a pivotal duty in improving both effectiveness and item quality within coffee production. By choosing top quality burr mills geared up with crucial functions such as flexible grind setups and durable building, companies can make certain optimum flavor removal. Regular upkeep is important for maintaining grinder performance and optimizing customer complete satisfaction. Inevitably, the strategic investment in a trustworthy grinder adds significantly to enhanced earnings and competition in the coffee industry.

In the affordable landscape of coffee manufacturing, choosing the best industrial coffee mill plays a crucial duty in boosting both effectiveness and item quality. The 2 main types of mills are blade mills and burr grinders. Within the burr grinder category, there are flat burr grinders and cone-shaped burr mills, each with its benefits. Burr grinders are usually preferred over blade grinders, as they give a consistent work dimension, which is crucial for ideal removal and taste.

In recap, a commercial coffee mill plays a critical duty in enhancing both performance and item high quality within coffee production.

Report this page